Our solutions

U-series robotic grinding cell

U-series robotic grinding cell

For heavy-duty and complex grinding processes

The U-series robotic grinding cell is specifically developed for maximum flexibility. This grinding cell can be perfectly adapted to your process, as the robot, control system and (rotary) table operate as independent units.

This enables the handling of large workpieces, the use of multiple work zones and seamless integration into existing production processes.

This enables the handling of large workpieces, the use of multiple work zones and seamless integration into existing production processes.

The result? A high-performance sanding, grinding and polishing process.

Key specifications:

- Flexible concept

- Large working range (up to 14 metres in length)

- Fully integrable with existing production lines

- Wide range of expansion options available

Applications

Deburring

Removing sharp edges and burrs after laser cutting, milling or punching.

Sanding en grinding weld seams

Grinding weld seams on flat, curved and complex geometries, including corner joints.

Polishing

Precision finishing of metal, plastic or wooden surfaces to a high-gloss finish.

Surface preparation

Structuring surfaces to improve the adhesion of coatings or paint layers.

Finishing of bodywork and engine parts.

Consistent grinding and polishing performance in the automotive industry.

Finishing of medical implants and instruments

High-precision finishing compliant with stringent quality and safety standards.

Grinding and polishing of aerospace components.

High-precision machining of turbine blades and composite components.

Refining furniture and wood surface finishes.

Efficient, consistent finishing of wooden panels and interior components.

Sanding of plastic and composite materials.

Removing surface irregularities and enhancement of surface structures (e.g. a matt finish).

Would you like to know what Cibo Robotics can do for you?

Discover how our robots can automate and enhance your grinding process.

We offer a completely free, no-obligation audit of your process and provide clear insight into the possibilities.

Highlights

Our latest, highly advanced tool change station (optional) greatly enhances the autonomy of the robotic grinding cell.

Tool change station

The accessories, integration capabilities, expandable working area and high-performance software ensure that you can scale up without wasting resources.

Future proof

The robot cell is equipped with an 18-inch touchscreen.

Its easily interpretable interface enables an operator to control the robot after just half a day of training.

Touchscreen

All our grinding cells are equipped with our in-house designed Maxerade® unit.

Maxerade®

Options

Tool change station

The robot can automatically change tools, allowing it to perform different grinding steps consecutively.

Grinding sheet exchange system

Automatic changing of sanding discs, different grit sizes and diameters can be carried out quickly and fully autonomously – even for discs and sheets up to 10 mm thick.

Synchronous turntable

Adding a turntable increases the robot arm’s reach and significantly reduces programming time.

Indexing table

Instead of sliding doors, we can install an indexing table with two synchronous turntables of fixed tables, or a combination of both.

Synchronous track

Increase your working range by adding a track.

Comparison of U-series robotic cell models

U160

High-speed precision unit for fine grinding and polishing

With a payload of up to 40 kg and a reach of 1,710 mm (2,010 mm in the L-variant), the TX2-160 is ideal for surface applications requiring constant medium contact force and high path accuracy.

U200

A powerhouse with extended reach for aggressive grinding and heavy-duty polishing.

For large workpieces or heavy stainless steel tool interfaces, the U200 is the logical choice: with a payload of up to 170 kg and a working range of up to 2.6 m (L-variant), it has the capacity to process complete surfaces in a single setup.

We will assist you in making the right decision.

Please contact us for a free audit.

Infinitely customisable, endless possibilities

Detailed specifications

U160

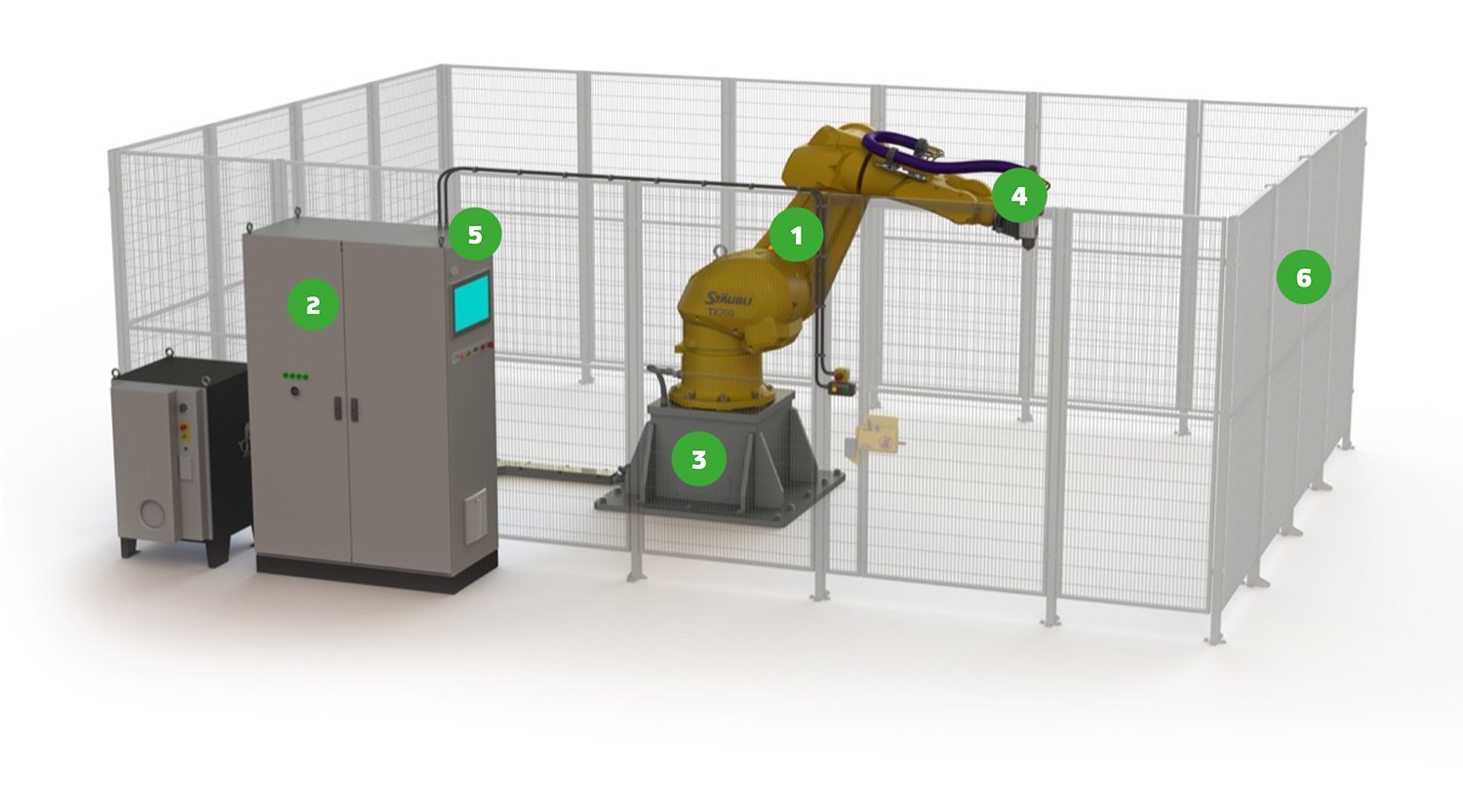

1. Robot

- Robot arm length: 1.710 mm

- Payload capacity: 40 kg nominal

- Repeatability (ISO 9283): +/- 0,05 mm

- IP65/IP67

Electrical grinding cabinet

- 18” touchscreen for operation

- Featuring integrated control buttons

3. Robot mounting base

- Welded construction with integrated space for electrical and pneumatic components

- Milled top surface with recess for the robot interfaces

4. Maxerade® grinding motor

- Tool for achieving perfectly even grinding, polishing or deburring on any workpiece

- The force applied by the motor to the surface can be set through the software.

- Robust and dependable quick-change system utilising our in-house HSK 32C mounting system.

- 4 kW power

- Max. rpm: 6,000

- Self-cooled motor

- IP 64

5. Control System

- Built as a CNC-style control system with simple, user-friendly operation

- The main screen provides an overview of all process parameters

- Capability to execute multiple programmes sequentially

- Support for working with multiple zero points

- Integrated tool table

- Audit en I/O overview

- Handheld unit allows easy manual robot operation

- Ability to open CNC files from various storage devices

6. Omkasting

A customised enclosure tailored to the customer’s needs.

U200

1. Robot

- Robot arm length: 2.600 mm. (L-version 2.400 mm.)

- Payload capacity: 170 kg nominal (L-version 110 Kg nominal)

- Repeatability (ISO 9283): +/- 0,05 mm

- IP65/IP67

2. Electrical grinding cabinet

- 18” touchscreen for operation

- Featuring integrated control buttons

3. Robot mounting base

- Welded construction with integrated space for electrical and pneumatic components

- Milled top surface with recess for the robot interfaces

4. Maxerade® grinding motor

- Tool for achieving perfectly even grinding, polishing or deburring on any workpiece

- The force applied by the motor to the surface can be set through the software.

- Robust and dependable quick-change system utilising our in-house HSK 32C mounting system.

- Available in 2 versions:

- 4 kW and 6 kW power

- Self-cooled motor

- Max. rpm: 6,000

- IP 64

5. Control System

- Built as a CNC-style control system with simple, user-friendly operation

- The main screen provides an overview of all process parameters

- Capability to execute multiple programmes sequentially

- Support for working with multiple zero points

- Integrated tool table

- Audit en I/O overview

- Handheld unit allows easy manual robot operation

- Ability to open CNC files from various storage devices

6. Omkasting

A customised enclosure tailored to the customer’s needs.

The U-series in action

Deburring of CNC-machined steel chassis

Internal weld-seam grinding on coupling components (Packo)

Comparison table

S-series | U-series |

All-in-one robotic grinding cell in an enclosure with sliding doors | Robotic grinding cell with fully separated components for optimal integration and modular expansion |

Multiple grinding processes executed autonomously on shapes ranging from simple to highly complex. | Multiple grinding processes executed autonomously on shapes that range from simple to highly complex and large geometries. |

Simplified parameter setup | Simplified parameter setup |

Ency CAM software

| Ency CAM software

|

|

|

Operating range: 750 x 500 x 500 mm

| Operating range: 2000 x 1200 x 500 mm (With a track, the maximum length is an impressive 14 metres!)

|

Fully operational within one day after installation. | Fully operational within a week after installation. |

Body Cell

|

Did you know that selecting the right abrasive material is crucial for high-performance automation? Read more about it in our blog.

"Our parts are large and complex, with strict quality requirements. We were looking for a process that was not only high-quality but also perfectly reproducible. For us, a robot turned out to be the ideal solution."

Discover the success story of IGW with the U200 robotic grinding cell

Discover moreMore information

The Cibo Robotics team is ready to assist you

Our dedicated team of specialists is ready to work with you to find the best automation solution for your sanding, grinding, or polishing process.

Contact